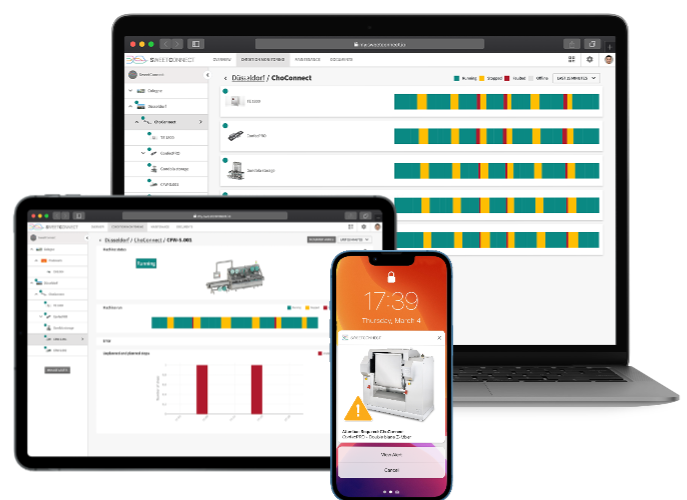

A single digital platform to plan, monitor, maintain and optimise your production.

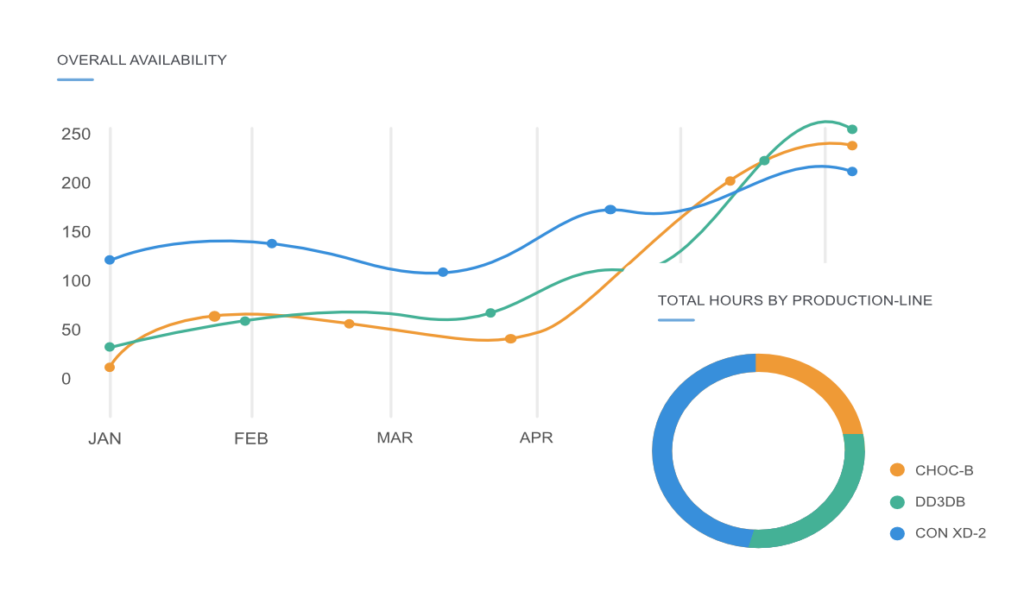

Management & Controlling

Access critical data to be one step ahead

One tool to access key-information, production figures and reports, to identify potentials for optimisations and to increase the profitability of your business.

Industry 4.0

Consolidation of vital key information

Reporting

Reporting, like OEE (Overall Equipment Effectiveness)

Analytics

Data-based analysis and optimizations

Performance

Comparisons of cost and performance figures

Visualisations

Visualisation of data for management

Database

Access current and historic production figures

Manage, plan and optimize based on real-life data

SweetConnect is specifically developed for the efficient and profitable production of confectionery and provides the necessary insights to manage confidently.

- Performance optimization

- Quality assuarance

- Cost & waste reduction

- KPI comparison

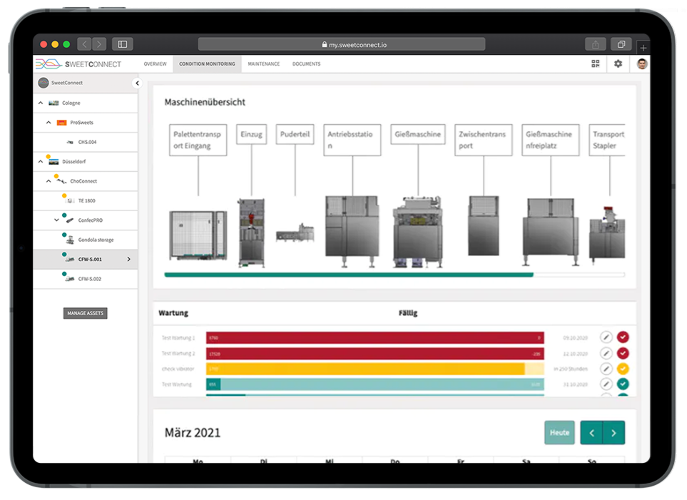

Production

Make your production run like clockwork

Access live-data, historical production-data, costings, and processes to plan, run and manage productions more effectively and efficiently.

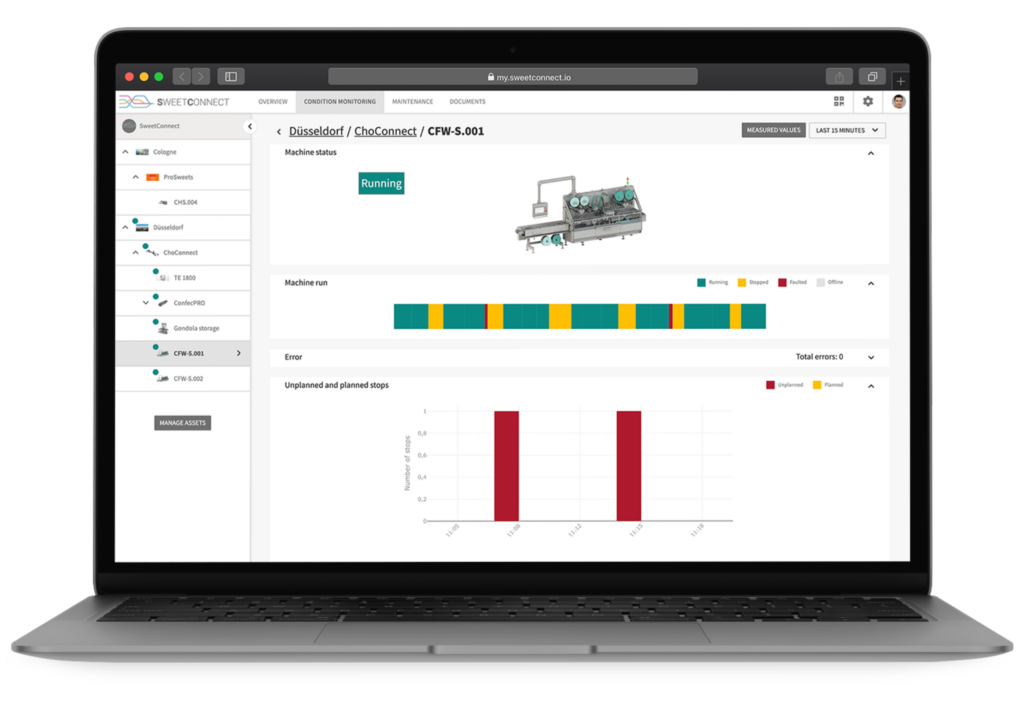

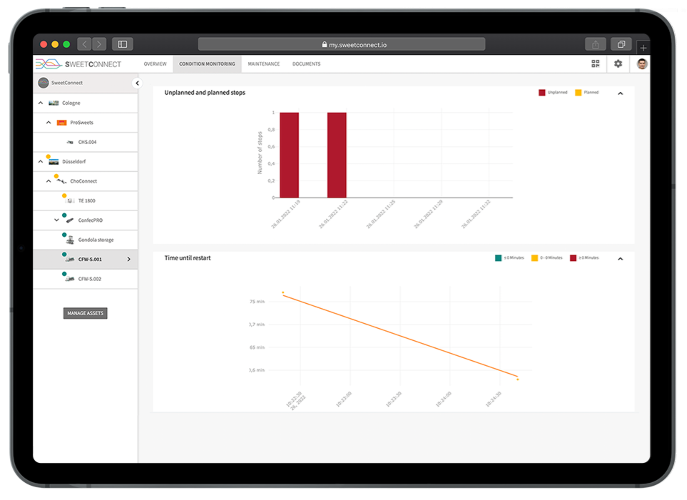

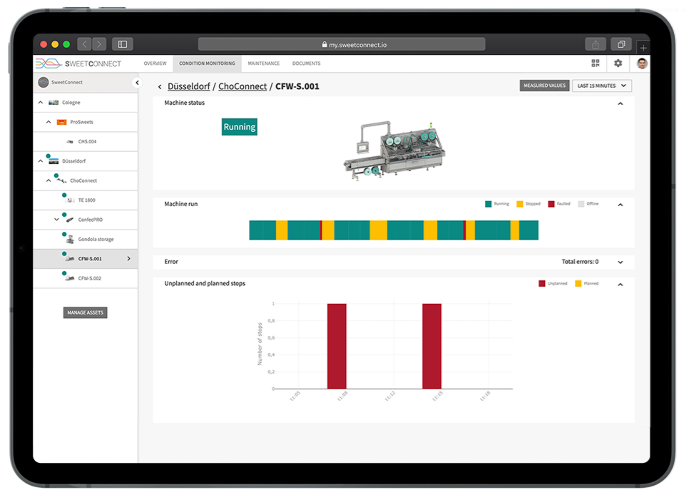

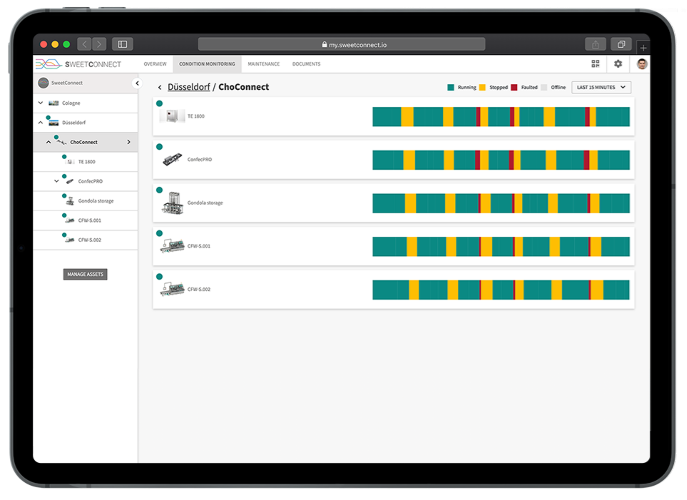

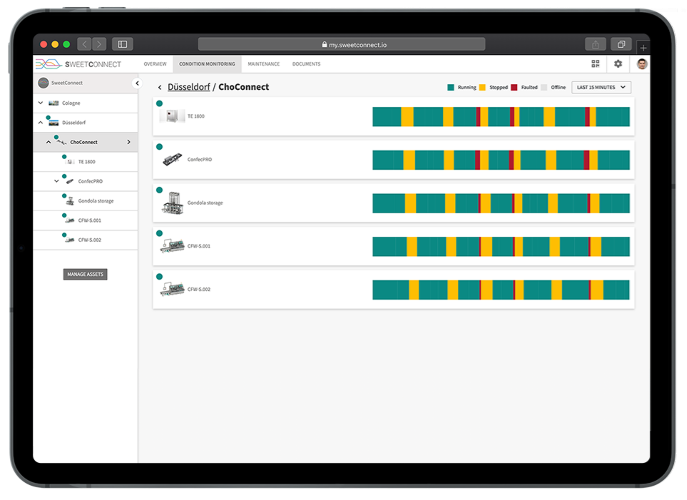

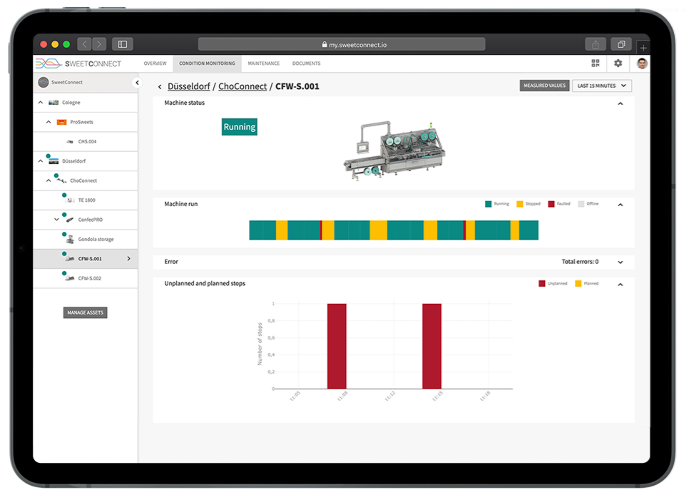

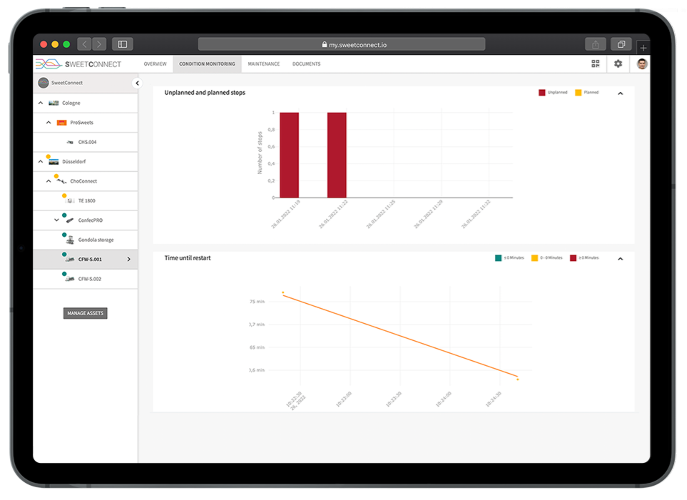

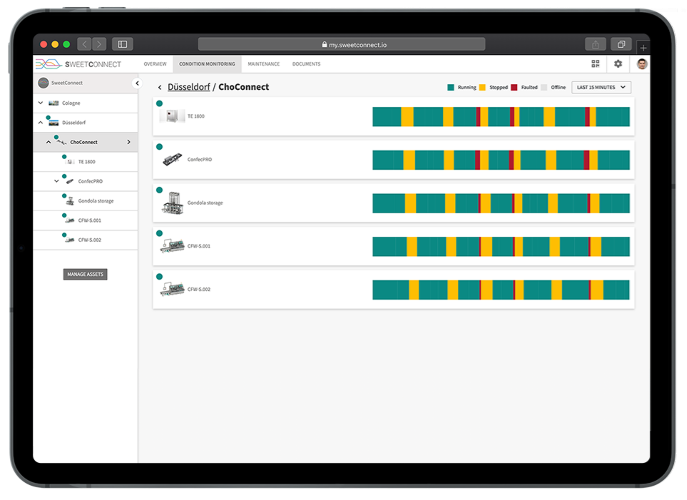

Condition Monitoring

Monitoring of ongoing productions

Analytics

Access to live-data and historical data

Access Remotely

Remote managing and monitoring

Produce intelligent, effective and efficient

SweetConnect provides a comprehensive overview of historic, current, and upcoming productions and gives certainty that everything goes according to plan.

- Downtime prevention

- Cost & waste reduction

- Performance optimization

- Quality assuarance

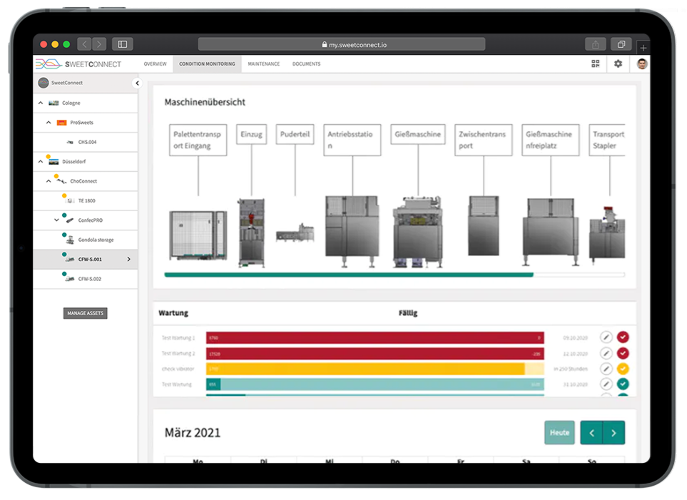

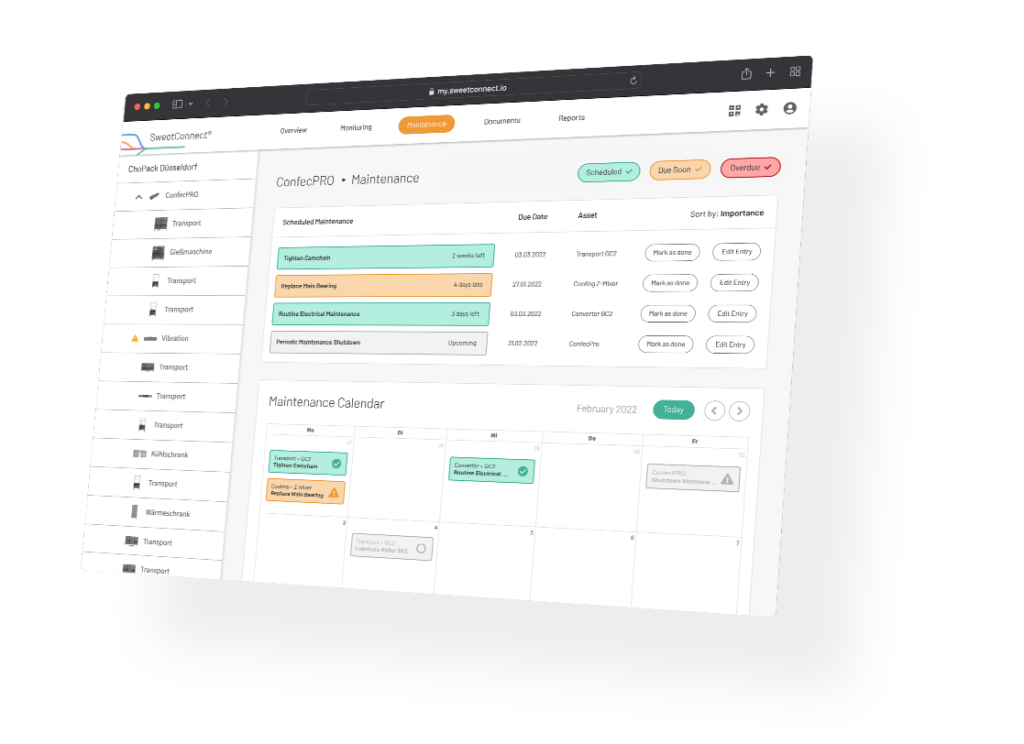

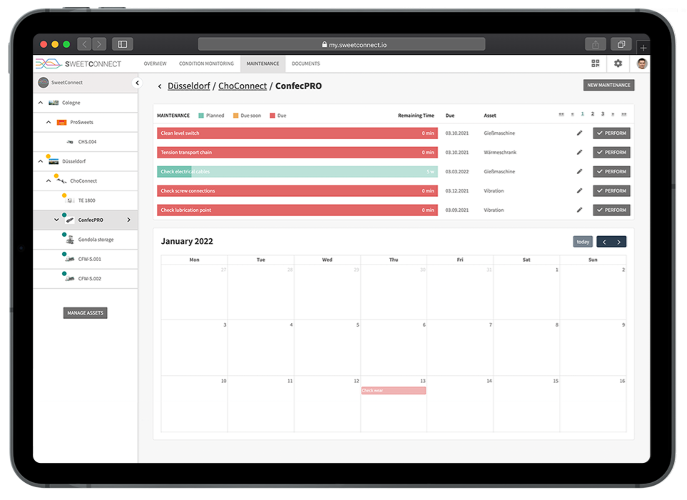

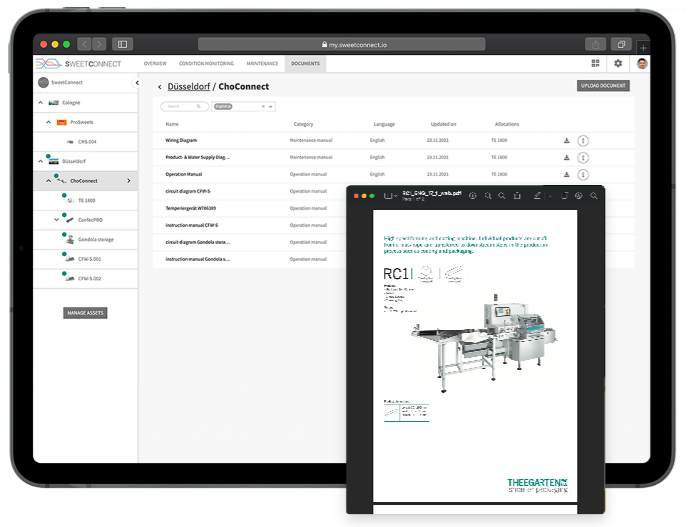

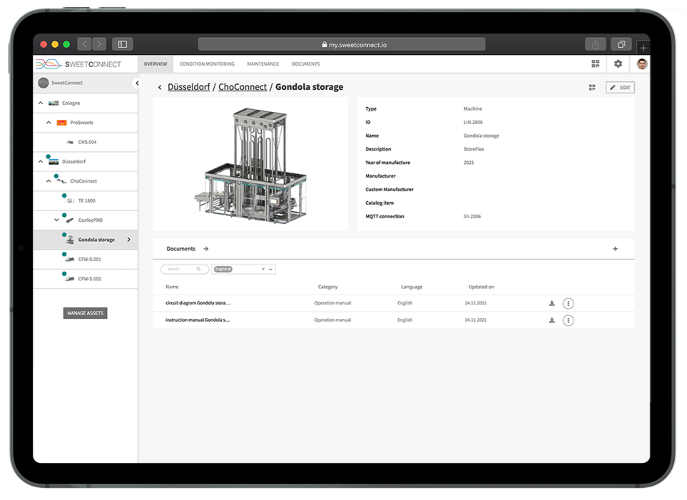

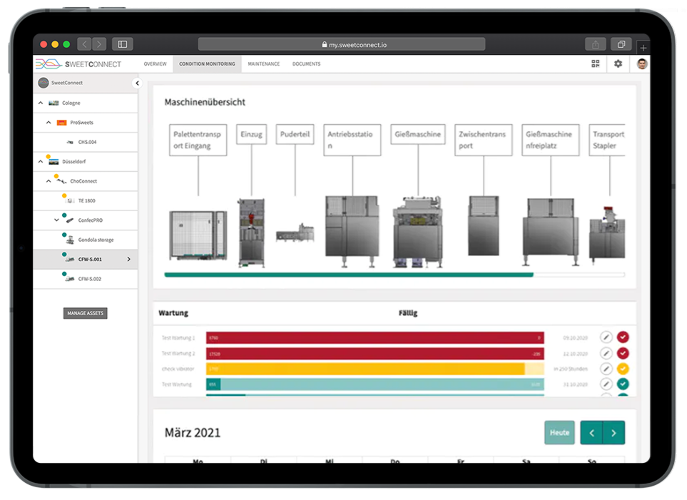

Maintenance

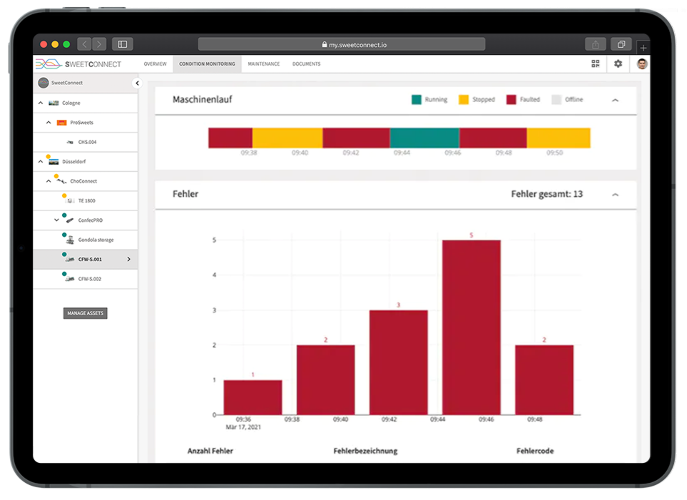

Solve problems before they appear

Our proactive monitoring system automates maintenance routines and provides key-information at the right time to improve availability and efficiency.

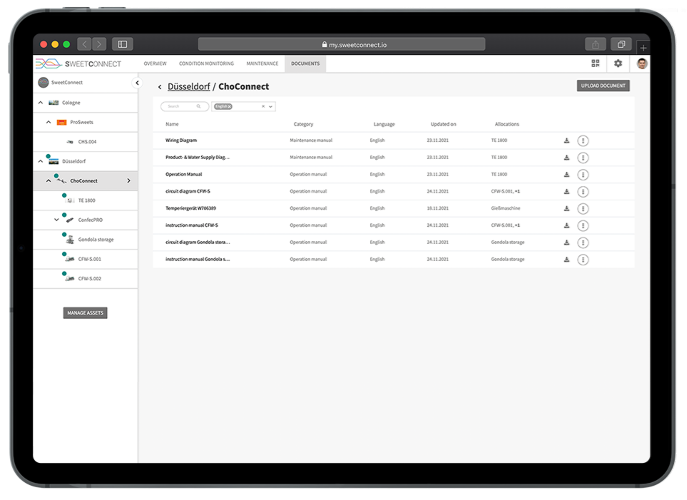

Planning

Integrated maintenance and service calendar

Repair support

Troubleshooting for malfunctions of equipment

Documentation

Digital library for machine and service manuals

Replacements

Access to catalogs of replacement items

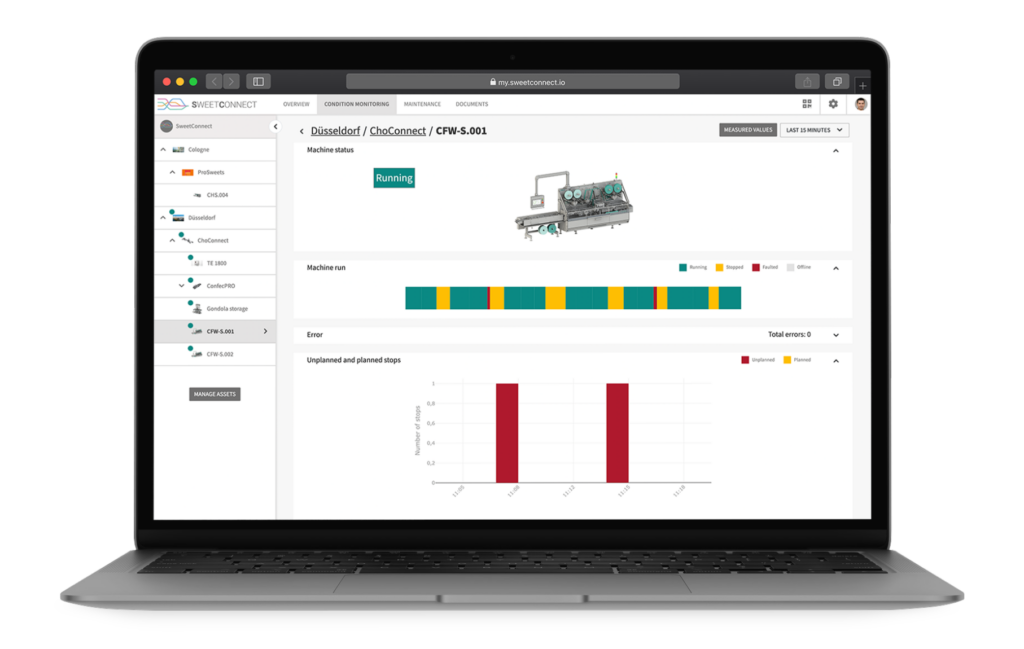

Condition Monitoring

Fault-finding across the entire machine park

Stay on top of things and get notified before things go wrong

SweetConnect reminds you of upcoming maintenance schedules, gives warnings of critical machine events, and automatically notifies staff on their device.

Status of components

Check the status of entire production lines and machines down to single components.

Remote Fault-Finding

Monitor the production remotely, get notified and identify faults from your device.

Technology & Security

A platform built for the future of the industry

A system built on an open framework, using industry standards to ensure long-term compatibility, advanced security and uninterrupted availability.

Industry 4.0

Connects to all machines and production-lines

Data Authority

Strict data separation of different producers and machine builders

Industry Standards

Developed using industry standards (e.g. OPC-UA)

Security

Stored on cloud servers in europe using latest security standards

Online Access

Available 24/7 on every device with internet access

Future-Proof

Scalable and future-proof due to modular configuration

Secure, compatible, modular – and made in Germany

SweetConnect is built in line with industry standards to ensure compatibility. A modular setup ensures it can scale with and adapt to your company’s requirements.

- Advanced data authority

- Customizable and extensible

Frequently Asked Questions

Does SweetConnect support my machines?

SweetConnect integrates seamlessly with any equipment of any manufacturer or brand and into any existing workflow.

Is SweetConnect available yet?

SweetConnect is currently being rolled out to machine manufacturers and confectionery producers that have joined our initiative.

Can existing SaaS solutions be connected?

We develop using industry standards with an open API. However, due to the variety of software available, compatibility needs to be assessed case by case.

How can I get involved in the initiative?

Get in touch to find out more about the SweetConnect initiative or schedule a callback or appointment.

Get started

Get in touch to schedule a free demo

If you do not feel like using the form below, you can always get in touch with us by emailing us, giving us a call or getting in touch on Linked-In.